Urban economic developers are experimenting with novel strategies that leverage the maker movement to revitalize American manufacturing. To paraphrase the Brookings Institute, the maker movement consists of independent designers and “tinkerers” that use online marketing platforms like Etsy or Grommet, along with new digital technologies to “democratize manufacturing and reinvigorate small-batch, craft production and sales.” As a place-based strategy, support for the maker-movement has much to offer, including inspiring the next generation of product designers and entrepreneurs and infusing creativity and innovation within established public institutions.

But if a primary goal is to engage this movement to help ‘catalyze a renaissance’ in American manufacturing and advance good paying, blue-collar jobs in the process, then we need strategies that also connect this new generation of urban designers to non-metro manufacturing communities. In other words, strategies that forge interdependencies between urban and rural communities and between America’s blue-collar workforce and its tech-savvy, socially-mind millennial population. Without these interventions, we risk further concentrating modern manufacturing within large metropolitan regions and undermining opportunities for smaller, rural communities to update their legacy manufacturing industries and talents.

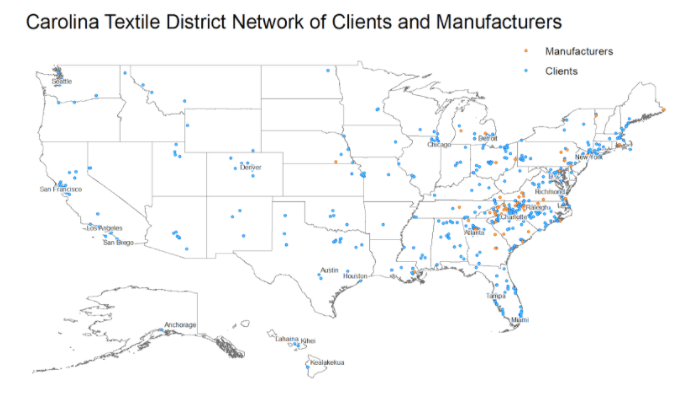

This cross-regional, inter-generational push is at the heart of the Carolina Textile District (CTD) —an innovative ‘value chain’ network that connects traditional manufacturers in North Carolina’s textile heartland with younger generations of urban-based clothing and textile designers. The CTD was founded in 2013 and supports over 120 textile-related manufacturers and production specialists dispersed throughout the Carolina’s and beyond. The CTD’s headquarters is located in Morganton, North Carolina, a small town with a population of a little more than 16,000.

CTD member manufacturers include everything from cut and sew operations, to pattern makers, to specialized textile factories, including high-tech fabric producers. The vast majority of these manufacturers are concentrated along the I-85 and I-40 corridors in North Carolina, with additional clusters in neighboring states that also boast a longstanding textile and apparel making tradition.

Over 1,200 clothing and textile designers have turned to the CTD since 2013 to find a manufacturing partner, either to produce a small sample batch or if successful with marketing, to complete a larger production run. The majority of these client designers are between the ages of 20 and 40 years old and most plan to sell their products online.

The CTD was launched as a unique partnership between a worker-owned, cut and sew cooperative (Opportunity Threads), a state-supported manufacturing technology center (Manufacturing Solutions Center) and the Burke County economic development agency. Opportunity Threads worked with the Manufacturing Solutions Center after being inundated by requests from young clothing designers looking to manufacture their product lines in the United States and hoping to contract with firms that met ethical and environmental production standards—something Opportunity Threads had committed to since its launch in 2008. That initial exchange between Opportunity Threads and the Manufacturing Solutions Center motivated the formation of the CTD network to meet “modern” textile demand.

The CTD integrates its support for American manufacturing resilience and job retention with ambitious principles of environmental sustainability and equity, including a commitment to living wage, quality jobs. Admittedly, these are aspirational goals, as few Carolina-based manufacturers currently meet all three standards. But rather than limit their engagement to only those few firms, CTD has adopted a more inclusive and transformational approach. CTD works closely with established manufacturers to encourage them to reduce product waste and improve working conditions and pay. It also requires actions on the designer side—namely, the CTD intervenes to promote designer success in business, with the goal to expand designer influence in the textile marketplace and elevate their role in shaping higher production standards.

On the design side, a key sticking point emerges when a new textile designer is not yet ready to connect with a domestic manufacturing partner. Some designers reach out to make the connection before they have a viable product design. Others have not done sufficient market research to determine the price point for a product and how to cost it out for downstream manufacturing. And still others struggle to develop a sound financial model or business plan. The CTD recognizes that too many interactions with unprepared designers could reduce a manufacturer’s desire to engage others like them in the future. If fact, some Carolina-based manufacturers acknowledge they have stopped answering emails or phone calls, knowing it could lead to wasted time advising young designers with no subsequent manufacturing demand.

As a solution, the CTD has created a mandatory screening mechanism, which has evolved into an online application process with a self-assessment tool—this process helps raise awareness within the textile entrepreneur community of the need for better preparation, but also enables the CTD to encourage less prepared designers to enroll in one of their workshops or webinar courses that walks them through the entire production process. Through courses like Sewn Goods 101, designers come to understand why it is so essential to have a price, a sample, and a delivery date, and a basic understanding of the industry before making that manufacturing connection. Dan St. Louis, a co-founder of the CTD, says it’s a win-win solution where “the entrepreneur gets to try their product…[and]…[t]he manufacturer gets a new vetted client and an opportunity to be involved in some of these new products that might come out.”

But how is CTD pushing equity and sustainability?

Admittedly, the CTD is hesitant to push their member manufacturers too hard on adopting sustainability and fair labor goals, primarily because of the associated cost. “You need to show them the potential business if they do incorporate these values. You have to lead them to the opportunity to change rather than strong arming them” says Tanya Wade, the CTD’s Project Coordinator. To ease this transition, the CTD offers a nested set of supports, including a series of gatherings that provide resources for their members. The CTD also puts emphasis on succession planning, seeing this as a channel to elevate sustainability and equity concerns through employee ownership and strategies in support of workplace democratization. As an additional step, they also help older, boomer-age manufacturers transform abstract concepts like equity and sustainability into tangible, cost-saving solutions. With this in mind, the Industrial Commons, a CTD sister organization, is launching a new recycling initiative to turn textile waste into a source of revenue generation, raising additional money to support manufacturing services.

With this and related efforts, the CTD is in a position to engage manufacturers that might have little initial interest in their environmental, social and economic sustainability objectives. They work with firms to help them see more immediate value within this guiding principal. But more broadly, they are creating an adaptive institutional platform, combining growth opportunities in legacy manufacturing with progressive economic, social and environmental principles. In this respect, the CTD offers a timely model for harnessing the creative energy of young urban designers in order to motivate rural manufacturing communities to reposition themselves as centers of ethical sourcing.

Featured Image: Carolina Textile District. Photo Credit: Carolina Textile District.

About the Authors: Nichola Lowe is Associate Professor of City and Regional Planning at UNC-Chapel Hill. Her work focuses on the institutional arrangements that lead to more inclusive forms of economic development and specifically, the role that practitioners can play in aligning growth and equity goals.

Colleen Durfee is a graduating Master’s student in City and Regional Planning at UNC-Chapel Hill where she specializes in hazard mitigation and economic development planning. She is interested in how depressed communities reinvent themselves through innovative economic development strategies and ultimately make them more resilient to future shocks.

Tara Vinodrai is Associate Professor and Director of the Master of Economic Development and Innovation program at the University of Waterloo (Canada). Her work focuses on the dynamics of urban and regional economies, including understanding of the role of policymakers, planners and practitioners in shaping pathways towards widespread prosperity.